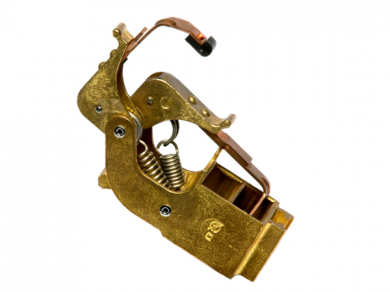

Brush-holders for DC motors

DC motors brush-holders: characteristics

- Robust

- Molded or machined

- Pressure systems (wound or coil springs)

- Single or multiple box

- Insulating studs

- Brush-holder attachment arm

- Brush-holder and rocker ring

Manufacture

- 3 manufacturing plants on 3 continents

- Selected materials (non-ferrous alloys, anti-corrosion...)

- Customized designs

- High quality solutions

- Cutting-edge equipment and software (CNC machines, binding machines…)

- Die casting

- EDM machining

- High-precision checking instruments (three dimensional CMM…)

- International standards (ISO 9001, IEC, NEMA, DIN)

DC motors: applications

- Electric and Diesel Electric Locomotives (traction motors)

- Subways (traction motors)

- Streetcars (traction motors)

- Trolleybuses (traction motors)

- Oil & gas (drilling, lifting, pump and anchor motors)

- Mining (draglines, shovels, wheel motors for front loaders and trucks, conveyors)

- Paper plants (paper machines, winders)

- Metallurgy (rolling mills, winders, wire drawing machines, extruders, winding machine)

- Cement plants (furnace motors, ventilators, ground or aerial conveyors)

- Plastic Industry (extruders)

- Aerospace (auxiliary motors)

- Forklifts (lifting motors, traction motors)

- Elevators (lifting motors)

- Ports & marine (lifting motors for cranes and gantry cranes, propulsion motors, onboard motors)

Related Products

Contact India

Bangalore Sales Office

Anekal Taluk

560 099 Bangalore, Karnataka

+91 80 68455121

Bangalore Sales Office

Anekal Taluk

560 099 Bangalore, Karnataka

+91 9611886785

+91 80 68455124

+91 80 68455125

Bangalore Sales Office

Anekal Taluk

560 099 Bangalore, Karnataka

+91 9900950430

+91 80 68455121

Bangalore Sales Office

Anekal Taluk

560 099 Bangalore, Karnataka

+91 80 68455123

+91 9972750838

Kolkata Sales Office

+91 961 128 5330

Bangalore Sales Office

+91 942 420 1402

Contact India

Bangalore Sales Office

Anekal Taluk

560 099 Bangalore, Karnataka

+91 80 68455121

Bangalore Sales Office

Anekal Taluk

560 099 Bangalore, Karnataka

+91 9611886785

+91 80 68455124

+91 80 68455125

Bangalore Sales Office

Anekal Taluk

560 099 Bangalore, Karnataka

+91 9900950430

+91 80 68455121

Bangalore Sales Office

Anekal Taluk

560 099 Bangalore, Karnataka

+91 80 68455123

+91 9972750838

Kolkata Sales Office

+91 961 128 5330

Bangalore Sales Office

+91 942 420 1402